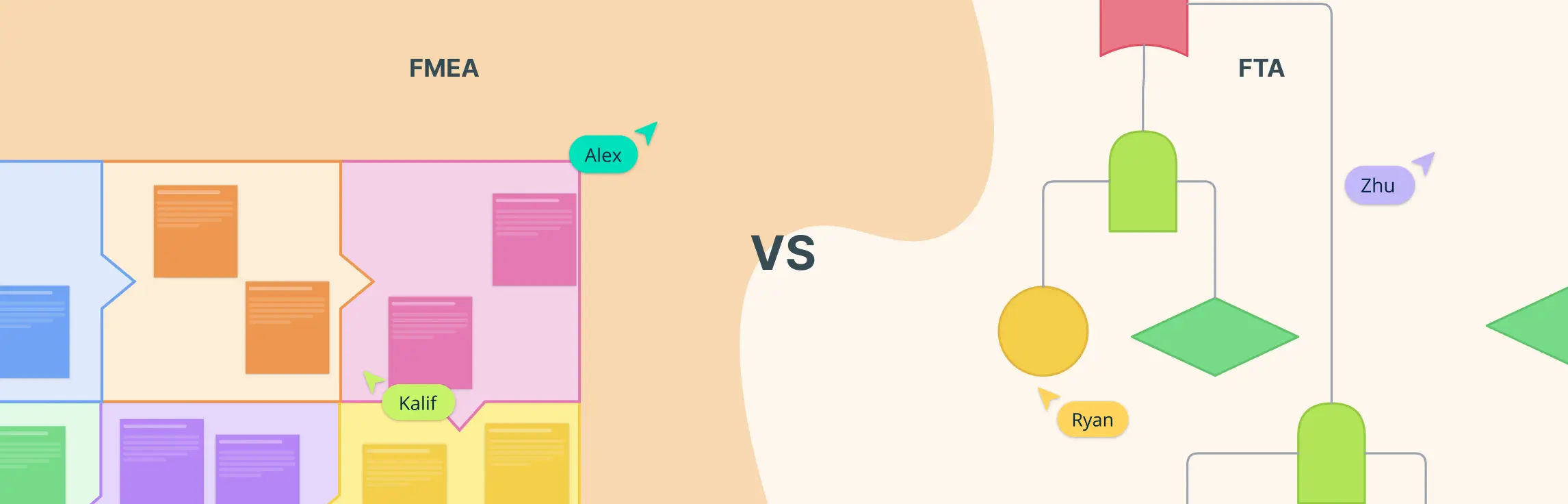

Introduction to FTA vs. FMEA

What is FTA?

Fault Tree Analysis (FTA) is a method used to understand how complex systems can fail and identify the root causes behind those failures. Fault Tree Analysis starts with a top-level issue, such as a system-wide failure, and works backward to break down contributing factors. This top-down approach is particularly useful for assessing the likelihood of critical failures and planning mitigation strategies.

FTA often uses visual diagrams to map out how different factors are connected, making it easier to analyze problems systematically. It is commonly applied in industries where precision and reliability are crucial, such as aerospace or nuclear power.

What is FMEA?

Failure Mode and Effects Analysis (FMEA) takes a proactive approach to understanding how individual components might fail and how those failures could impact the overall system. Using an inductive method, FMEA looks at each possible failure and traces its effects, providing a detailed view that is especially useful during the design phase or for ongoing quality assurance.

Unlike FTA, which uses visual diagrams, FMEA organizes its findings in a tabular format, making it easier to systematically analyze and prioritize potential failures. This approach not only highlights areas of concern but also helps identify preventive actions to address them.

Both FTA vs FMEA are important tools in risk management and improving system reliability. While FTA focuses on quantifying risks and understanding how failures happen at a system level, FMEA dives into the details to prevent issues before they occur. Together, these methods offer a comprehensive approach to risk assessment, particularly valuable in industries like aerospace, automotive, and healthcare, where safety and reliability are critical.

You can explore FMEA further using the Failure Mode and Effects Analysis Template by Creately, which provides a structured way to document and assess potential failures effectively.

Methodological Differences Between FTA vs FMEA

Deductive Approach of FTA

Fault Tree Analysis (FTA) uses a deductive, top-down approach to analyze failures. It starts with a specific top-level event, such as a system failure, and works backward to uncover the root causes. By using a graphical representation, FTA provides a clear and structured way to understand failure mechanisms within a system.

FTA uses FTA symbols like AND and OR to show how failures are connected to their causes. This makes it especially useful for analyzing how different events combine to lead to a specific failure. FTA’s ability to quantify the likelihood of these failure events makes it well-suited for safety-critical systems.

This approach is commonly used in industries where precise risk assessment is critical, helping organizations identify and mitigate system-wide risks effectively.

Inductive Nature of FMEA

Failure Mode and Effects Analysis (FMEA) takes an inductive, bottom-up approach to risk analysis. It starts by examining individual components of a system, looking at all the ways each part could fail and the potential impacts of those failures. FMEA uses tables instead of diagrams to list problems and how to fix them.

This method is especially useful during the early design stages, where it helps identify and address potential issues before they occur. By focusing on preventative actions, FMEA improves product reliability and performance while supporting quality assurance efforts. It is widely used in industries like automotive and healthcare, where safety and reliability are critical.

For a structured way to apply FMEA, check out the FMEA Template by Creately, designed to streamline this process.

Understanding the differences between FTA vs FMEA allows risk analysts and quality managers to choose the right method for their needs. Combining both approaches can create a stronger, more comprehensive risk analysis framework.

Here’s a summary of the differences discussed above:

| Aspect | FTA (Fault Tree Analysis) | FMEA (Failure Mode and Effects Analysis) |

| Approach | Deductive (Top-down analysis) | Inductive (Bottom-up analysis) |

| Focus | System-wide failures and interactions between components | Individual component failures and their effects on the overall system |

| Representation | Graphical (Fault tree diagrams) | Tabular (FMEA table with severity, occurrence, and detection ratings) |

| Strength | Quantitative risk assessment, probability analysis | Comprehensive component-level failure identification and prevention |

| Industries | High-risk industries (nuclear, aerospace, petrochemicals, defense) | Automotive, healthcare, manufacturing, electronics, and consumer products |

| Primary Goal | To identify and assess system-wide risks and failure probabilities | To identify potential failure modes of components and prioritize corrective actions |

| Granularity | System-wide analysis, focusing on top-level events | Component-level analysis, focusing on individual failures |

| Risk Assessment | Quantitative (probability-based) | Qualitative (severity-based) |

| Failure Mode Analysis | Focuses on complex interactions and dependencies that lead to failure | Focuses on how and why a component might fail, and its consequences |

| Tools Used | Logical gates (AND, OR), probability models | Risk Priority Number (RPN), Failure Mode, Effects, and Causes (FMEC) table |

| Ideal Stage | Ideal for mature systems, post-design, or operational environments | Ideal for early design, development, and manufacturing stages |

| Data-Driven | Relies on statistical data and historical incident reports | Relies on expert judgment and theoretical analysis |

| Failure Prevention | Identifies root causes to prevent top-level failures | Recommends design improvements or process changes to prevent component failure |

| Timeframe | Often used in long-term risk analysis and after incidents have occurred | Primarily used during early design phases or before mass production |

| Cost Implication | High initial cost due to complexity and need for data availability | Lower cost, especially in early design stages, as it identifies and prevents failures early |

| Risk Prioritization | Prioritizes risks based on the probability of catastrophic failures | Prioritizes risks based on the severity, likelihood, and detectability of failure modes |

| Collaboration | Typically involves engineers, system designers, and safety experts | Requires collaboration between engineers, designers, and quality teams |

| Use of Historical Data | Strong emphasis on historical data and probability distribution | Relies on experience and analysis of failure modes from similar systems or products |

When to Use FTA vs. FMEA

Scenarios Ideal for FTA (Fault Tree Analysis)

Fault Tree Analysis (FTA) works best in situations where understanding and managing system-wide failures is critical. It is commonly used in high-risk industries like aerospace, nuclear power, and petrochemicals because of its ability to analyze complex systems and calculate the likelihood of major failures.

When to Use FTA

High-Risk Industries: Perfect for sectors where failure consequences are severe, such as aerospace, nuclear power, and petrochemical industries.

Complex Systems with Interdependencies: Useful for analyzing systems with many interconnected parts, where one failure can lead to others.

Quantitative Risk Analysis: Ideal when a data-driven approach is needed to calculate failure probabilities using fault trees and logical gates.

Human Error or External Events: Effective for systems impacted by human mistakes or external factors, helping to understand their effects on system reliability.

Key Benefits of FTA

- Provides detailed, quantitative analysis of failure probabilities.

- Focuses on system-wide risks, especially top-level events and interactions.

- Works well for mature or operational systems where risk assessment is essential.

FTA is a great choice for identifying system-level risks and performing quantitative evaluations of potential failures. It’s particularly useful in safety-critical industries where understanding how different factors contribute to failures is a priority.

The fault tree analysis template above provides an intuitive visual framework to analyze these complex scenarios. It allows teams to identify the root causes of failures systematically, map out fault interactions, and simulate risk scenarios. By using this template, organizations can streamline the analysis process, ensuring a detailed breakdown of risks and preventive measures to enhance system reliability and safety.

Circumstances Ideal for FMEA

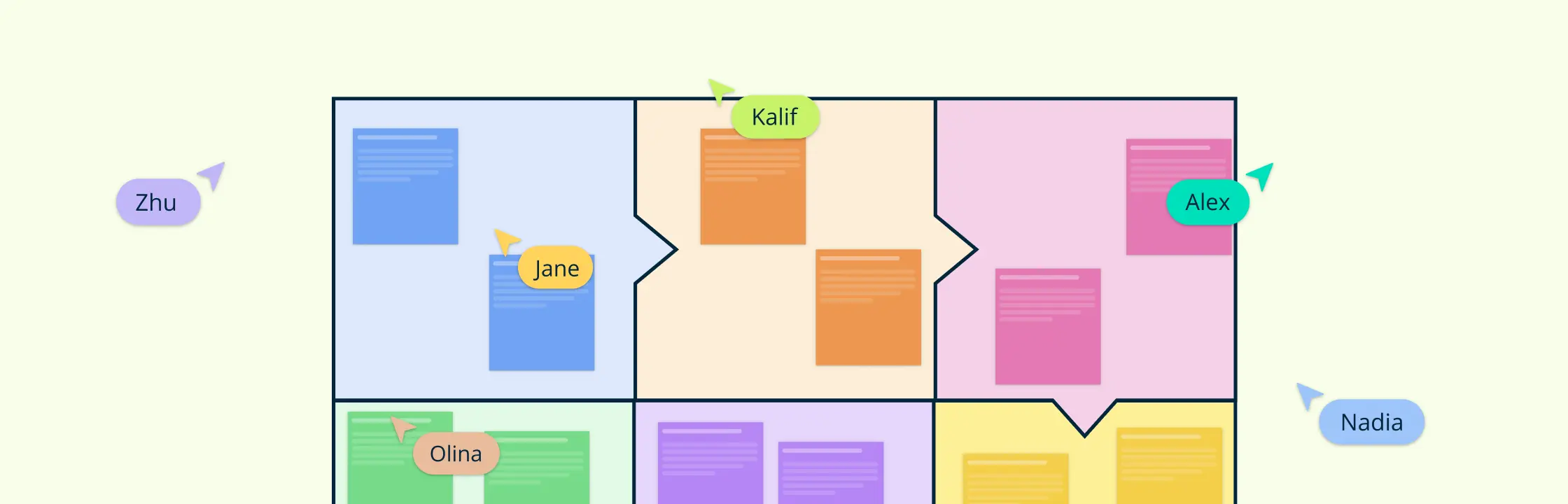

FMEA is most useful when analyzing individual components, especially during the early design stages. It helps identify potential failures and their impact on the whole system. Industries like automotive, healthcare, and manufacturing use FMEA to improve reliability and ensure quality.

When to Use FMEA

Early-Stage Design and Development: FMEA is helpful during the design phase to identify potential failure points early, allowing teams to take preventive actions and make informed decisions.

Component-Level Analysis: Ideal for situations where a detailed breakdown of potential failure modes for individual components is needed.

Quality Control and Preventive Maintenance: Supports industries like automotive and healthcare by guiding preventive actions to ensure product reliability and safety.

Precision Manufacturing: Helps maintain quality standards in industries with tightly controlled manufacturing processes, reducing defects and delays.

Key Benefits of FMEA

- Provides detailed analysis of individual components and their potential failure modes.

- Considers how each failure affects the system, prioritizing corrective actions effectively.

- Supports product design and improvement, helping create reliable and safe products.

FMEA is a useful tool for spotting problems early, improving quality control, and ensuring the reliability of each part in a system. It’s especially important during design and manufacturing when attention to detail matters.

The FMEA Analysis Template provides an easy way to document and assess potential failures, their effects, and causes. It helps teams prioritize risks and make improvements to enhance quality and reduce issues.

Helpful Resources

Evaluate the reliability, maintainability and safety of systems faster with this easy-to-use visual tool

Fault Tree Analysis Symbols: A Comprehensive Guide

What is Fault Tree Analysis and How to Create One.

Combining FTA and FMEA for Better Risk Analysis

Why a Hybrid Approach Works

Combining FTA and FMEA gives you a complete way to assess risks by using the strengths of both methods. FTA uses a top-down method to give you a big-picture view, showing how different components and factors can lead to major system failures. It’s perfect for industries like aerospace and nuclear power, where every detail matters. FMEA focuses on individual parts to catch problems early, which is important in design and manufacturing.

Why Combine FTA and FMEA together?

Big and Small Picture Insights: FTA gives you quantitative data on system-wide risks, while FMEA focuses on component-level details with qualitative insights. Together, they make sure nothing is missed.

A Complete Evaluation: This combo looks at how different parts of the system interact while also zooming in on specific failure modes.

Broad Use Cases: Industries that rely on safety and reliability—like healthcare, automotive, and nuclear power—benefit most from this holistic analysis.

Using FTA and FMEA together isn’t just about being thorough; it’s about making sure you’ve got both the high-level risks and the small details figured out. With this hybrid approach, you’re better equipped to create safer, more reliable systems, no matter how complex they are.

Role of Creately in Streamlining FTA vs FMEA

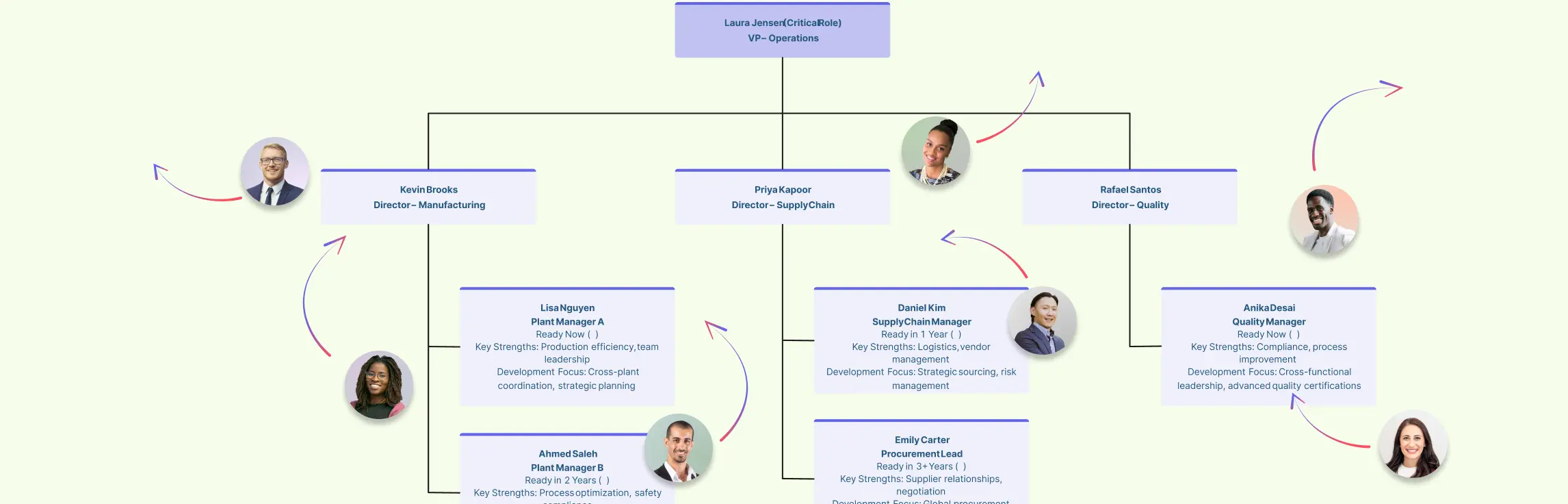

Creately is a great tool that makes it easier and more accurate to use FTA and FMEA together.Creately’s platform helps simplify risk analysis with tools for teamwork, clear visuals, and smooth communication.

Creately enhances risk analysis through three key features:

Enhancing Analytical Precision: Creately enables teams to create detailed visual diagrams for both FTA’s top-down and FMEA’s bottom-up approaches, ensuring a thorough risk assessment by visualizing complex relationships and failure modes.

Real-Time Collaboration: With real-time collaboration, teams can work together seamlessly across locations, incorporating feedback and ensuring faster updates and decision-making, leading to a more comprehensive analysis.

Process Mapping and Visualization: Creately’s process mapping tools—such as flowcharts, process maps, and timelines—help teams track complex processes, identify failure points, and visualize system interactions, ensuring better alignment and strategic decision-making.

Features for FTA vs FMEA Analysis

Customizable Templates: Creately offers pre-built templates tailored for both FTA vs FMEA, streamlining the analysis process.

Drag-and-Drop Interface: Easy-to-use interface for quickly building complex fault trees and failure mode diagrams.

Real-Time Collaboration & Feedback: Teams can collaborate in real-time, providing immediate updates and feedback.

Integration with Other Tools: Integrates with other platforms to pull in data, creating a holistic view of the system or process being analyzed.

Data-Linked Diagrams: Links diagrams to live data, making it easy to track changes and assess the impact of updates to risk factors.

Cloud-Based: Cloud storage enables secure access from anywhere, ensuring teams are always aligned and working with the most up-to-date information.

Creately is a vital tool for professionals using FTA vs FMEA in risk analysis. Its features, including real-time collaboration, data-linked diagrams, and powerful process mapping tools, enhance the precision and efficiency of risk assessments. By streamlining workflows and improving decision-making, Creately helps organizations achieve safer and more reliable systems.

Discover more about Creately’s Process Mapping Software and how it can transform your FTA and FMEA analysis strategy.

Conclusion

FTA vs FMEA are essential tools in risk analysis, each offering unique benefits. Fault Tree Analysis (FTA) uses a deductive, top-down approach to assess system-wide failures and quantify risks, making it crucial in high-risk industries like aerospace and nuclear power. In contrast, Failure Mode and Effects Analysis (FMEA) adopts an inductive, bottom-up approach to evaluate component-level failures and recommend corrective actions, which is invaluable in sectors like automotive and healthcare.

When comparing FTA vs FMEA, combining both methods provides a comprehensive risk assessment. FTA’s quantitative insights and FMEA’s qualitative approach work together to offer a well-rounded view of potential failures.

Modern tools like Creately enhance the FTA vs FMEA hybrid approach by offering visual workspaces, real-time collaboration, and process mapping, which streamline the analysis and decision-making process. By integrating both Fault Tree Analysis and Failure Mode and Effects Analysis, organizations can ensure a more robust risk management strategy that improves safety and operational reliability across industries.

Resources:

Consulting, E. (2015). Choosing between Failure Modes and Effects Analysis and Fault Tree Analysis - FMEA v FTA. [online] Egerton Consulting. Available at: https://egertonconsulting.com/fmea-v-fta/.

FAQs Related to FTA vs FMEA

What is the main difference between FTA vs FMEA?

When should I use Fault Tree Analysis (FTA)?

How do FTA vs FMEA complement each other?

What industries benefit most from FTA vs FMEA?

- FTA is crucial in high-risk industries, such as aerospace, nuclear power, and chemical sectors, where understanding the potential for system-wide failures is essential for safety.

- FMEA is widely used in industries like automotive, healthcare, and manufacturing, where early detection of failure modes and proactive corrective actions are necessary to ensure quality and reliability.